DMU 50 3rd Generation

CNC Universal Milling Machine with swivel rotary table

Highlights

5-Axis Machining with up to 20,000 rpm

- speedMASTER 15,000 rpm with 21kW and 111Nm in basic version

- speedMASTER 15,000 rpm with 46kW and 200Nm optionally available

- speedMASTER 20,000 rpm with 35kW and 130Nm optionally available

Swivel Rotary Table for 5-Axes Simultaneous Machining

- Table load up to 300 kg

- Swivel area of the B-axis -35°/+ 110° for highest flexibility

- Cooled table bearings for highest precision

Tool magazine with 30 pockets in basic version

- Loading of tools from the front even during machining

- Excellent visibility and accessibility

- 60 or 120 pockets optionally available

Precision

- comprehensive cooling concept for highest longterm precision

- one-piece machine bed

- direct driven ball screw drives

- direct path measuring systems in all axes

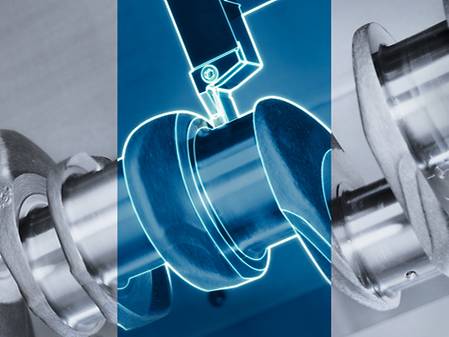

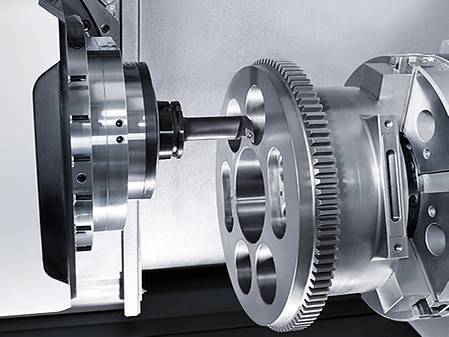

Application Examples

Automation

Standard automation and customized solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems:

Most compact and cost-effective pallet automation from DMG MORI

- Most compact and cost effective pallet automation system from DMG MORI

- Small space requirement of only 2.7 m2 (1.6 × 1.7 m)

- 3 CNC axes for high flexibility and precision

- Modular system with various tool pallet configurations for HSK-50, HSK-63, HSK-100, EROWA ITS, Schunk

- Flexible integration possible for a large number of DMG MORI machines

- Pallet Master – for convenient and simple control of the automation directly via the machine control

Universal pallet handling from DMG MORI

- Control directly via the machine control system

- High variability of available configurations from 24 round pallets of ø 148 to four 500 × 500 mm pallets

- Up to 150 kg workpiece weight as standard (optionally expandable to 250 kg)

- Possibility to prioritize orders

- EROWA clamping system as standard, SCHUNK optional

- High clamping repeatability (< 0.002 mm for the chuck EROWA UPC-P)

- Optimal accessibility to the machine and automation

PH Cell 300 - Modular pallet handling for up to 40 pallets

- Modular automation concept with up to 40 storage locations in a 10.7 m2 footprint

- Handling of different pallet sizes in one system

- Up to 300 kg transfer weight (workpiece incl. pallet)

- Separate setup station for ergonomic and simultaneous loading and unloading of pallets

- Convenient and simple control of the automation directly via the machine control panel

PH Cell Twin - Modular pallet handling for 2 machines and up to 30 pallets

- One pallet handling device for 2 machines

- Up to 30 pallets on 12.9 m² due to double row pallet storage on each level

- Workpieces up to 500 x 500 x 500 mm

- Up to 300 kg transfer weight (workpiece incl. pallet)

- Retrofit of the second machine possible

- Attractively priced automation in DMG MORI VERTICO design

Flexible workpiece handling for small to medium batch sizes

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Robo2Go Milling, robot payload 25, 35 or 70 kg

- Best-in-class layouts with right setup variant

- +12% capacity thanks to standard Euro pallets

- 32% higher capacity of the drawer storage

- Now with 50% more capacity: the pallet station with three Euro pallets

- Right-hand installation option for full accessibility to the working area, control panel and tool magazine

- Integrated in the machine control operation via Robo2Go APP: No need to change your NC programs!

- Job management of all jobs via the Robo2Go Jobs app

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- 300 % higher capacity compared to standard

- Main time-parallel setup of the workpiece storage

- Multijob per drawer and within a drawer possible in the standard system

Highly flexible and collaborative automation for workpieces up to 10 kg

- Freely movable workpiece handling, incl. robot and storage area on a trolley

- Workpieces up to 10 kg, or 5 kg x 2 with double gripper

- No infrastructure changes

- No safety fence necessary

- 600 × 900 mm footprint

- Collaborative robots, setup time <5 minutes*

- Direct teaching without robot knowledge

- Easy connection via Ethernet

- Two types of workpiece stockers can be selected

- Storage for up to 64 workpieces

- Blow-off device

- Regrip station

*When the optional tag position correction function is selected or when the machine / workpiece setup is already completed.

Individual workpiece handling for technology machines:

- Modular automation system for transfer weights ranging from 7 to 35 kg

- As a circulating storage system with a maximum workpiece size of up to 300 x 200 x 120 mm (other sizes available on request)

- Large storage capacity/autonomy for up to 3000 workpieces depending on workpiece dimensions

- Minimal space requirement for automation, from 1.5 m² for the WH Cell

WH Cell – Flexible automation system with large storage capacity

- Circulating storage system as a side-by-side solution in an enclosed cell

- Customized turnkey solutions with maximum workpiece storage density

- Extensive and standardized modules for handling and technology options

- Workpiece-specific system programming and special designs for individual automation requirements

- Fast program setup times and intuitive operation thanks to type management and simple program structures

Flexible automation system for both workpiece and pallet handling

- Payload: max. 210 kg (MATRIS WPH 210)

- Handling of workpieces (W x D x H) up to 340 x 250 x 250 mm (MATRIS WPH 210)

- Handling of pallet weight up to 150 kg (MATRIS WPH 210)

- Universal handling with hand changer

(Workpiece, Hand, Pallet, Shelf) - Drawer stocker for maximized capacity

- Movable shelves for variety size of fixtures

- Guidance-based HMI controller

- Quick installation & maintenance

High productivity and flexibility for variable-mix, variable-volume production

- Robot equipped with servo hand to handle a wide variety of workpieces:

Universal handling with hand changer (Workpiece, Hand, Pallet, Shelf) - Drawer stocker: Large stock capacity

- Pallet shelf: Movable shelves

- Pallet setup station with flat operating space:

Vacuum unit can be mounted as an option - HMI controller

- No code robot operation

- Quick recovery

- Message and Assistance

- Minimize setup time

Workpiece automation with maximum flexibility thanks to flexible layout design

- Modular concept with flexible layout design

- Driverless transport systems without guide rails or tracks

- Collaborative: human and machine in one system

- Vision sensor enables robot arm positioning accuracy better than ± 1 mm

- Workpieces up to ø 150 × 120 mm and 10 kg

- Compact design (700 × 1,035 mm)

- Laser sensor

- Excellent operational performance and stability, including on an uneven floor

Pallet automation with maximum flexibility through free layout design

- Modular concept with flexible layout design

- Driverless transport systems without guide rails or tracks

- Collaborative: Man and machine in one system

- Navigation through natural navigation

- Pallet sizes from 500 × 500 mm to 1,600 × 1,250 mm

- Workpieces up to 5,000 kg and ø 1,600 mm

Free accessibility

- Best visibility into the workspace at any time

- Manual or crane loading still possible

- Collaborative system – man and machine in one system

Modular concept with free layout design

- No safety housing for the automation system necessary

- Free positioning possibility of the individual modules

- Subsequent integration into existing production

Simple expansion of automation system

- Additional shelf modules to increase the number of storage places

- Additional AMRs can be integrated in the system

- Machines with an automation interface can be integrated very quickly afterwards

Minimum space requirement

- Free pallet handling system without fixed installation requirements on hall floor

- AMR paths remain walkable and passable

- Laser scanners guarantee personal protection in driving direction

- Omnidirectional movement for minimum space requirements (turning circle 0m)

- Flexible automation concept - Automation of different machine types with one system

Control & Software

- Individually customizable user interface with freely configurable windows

- Intuitive setup of workpieces with smart probing functions and graphically supported alignment of clamping devices

- Simple programming in HEIDENHAIN conversational programming or according to DIN/ISO

- Extensive machining and touch probe cycles

- High-end performance for perfect surfaces and maximum accuracy

- Dynamic collision monitoring and realistic for more safety

- HEROS operating system based on Linux for maximum IT security

- Standardized app-based user interface independent of the CNC control system

- Possibility of connecting the machine to the company organization

- Application for simple operation, extended spindle hours and increased energy efficiency

- Future-proof thanks to online update options

- Prepared for CELOS Xchange cloud connection

- NETserivce: Remote diagnostics and remote maintenance

- MDC: Standardized machine data output in OPC UA, MT connect and MQ TT formats

- Service Agent: Integrated maintenance manual

- 24” multitouch screen with horizontal screen orientation

- Full size tactile keyboard

- SMARTride potentiometer feed and rapid traverse combined

- SMARTkey in credit card format

- Ergonomic angle adjustment

- 3D Shopfloor Programming for workshop-oriented programming with automatic feature recognition

- Advanced Surface and Top Surface: best workpiece surfaces with minimum machining time

- Optimized PLC cycle times

- Comprehensive machining cycles

- Powerful multicore system architecture for smooth operation with maximum CNC performance

- Familiar look & feel

- Standardized app-based user interface independent of the CNC control system

- Possibility of connecting the machine to the company organization

- Application for simple operation, extended spindle hours and increased energy efficiency

- Future-proof thanks to online update options

- Prepared for CELOS Xchange cloud connection

- NETserivce: Remote diagnostics and remote maintenance

- MDC: Standardized machine data output in OPC UA, MT connect and MQ TT formats

- Service Agent: Integrated maintenance manual

- 24” multitouch screen with horizontal screen orientation

- Full size tactile keyboard

- SMARTride potentiometer feed and rapid traverse combined

- SMARTkey in credit card format

- Ergonomic angle adjustment

- DMG MORI specific user interface

- Extensive machining cycles

- Flexible display through 6-window display and arrangement in window sets

- 3D collision control and machining simulation

- Extensive machining cycles

- Tool Management System

- Possibility of connecting the machine to the company organization

- NETserivce: Remote Diagnostics and Remote Maintenance

- IoTconnector: Standardized machine data output in the formats OPC UA, MT connect and MQ TT

- Service Agent: Integrated Maintenance Guide

- 21,5” multitouch screen

- Lower touch screen with individual and adaptive functions

- SMARTkey with integrated USB drive

- Ergonomic angle adjustment

- DMG MORI specific user interface

- Extensive machining cycles

- Flexible display through 6-window display and arrangement in window sets

- 3D collision control and machining simulation

- Extensive machining cycles

- Tool Management System

- Possibility of connecting the machine to the company organization

- NETserivce: Remote Diagnostics and Remote Maintenance

- IoTconnector: Standardized machine data output in the formats OPC UA, MT connect and MQ TT

- Service Agent: Integrated Maintenance Guide

- 21,5” multitouch screen

- Lower touch screen with individual and adaptive functions

- SMARTkey with integrated USB drive

- Ergonomic angle adjustment

- Free form surfaces by 5-axis interpolation on the main and counter spindle

- Turning and milling with interpolated B-axis

- Programming the 5-axis movements via customer CAD / CAM systems

- An intellegent Look-ahead function for a continuous process

- Superposition of the turning movement by additional X- and Y-traverses

- Applicable for turning and milling

- Eccentric geometries easy to manufacture

- Exact axis coupling and synchronization in the background

- Highest flexibility in the machining of structural components due to variable alignment of the angle head

- Automatic CAD / CAM programming

- Automatic calculation of the TCP and combination with existing control functions

- Vibration monitoring in the process

- Rapid shutdown in case of a crash

- Manual retraction even in swiveled machining plane

- NEW: Torque monitoring

- New: Recommended with Protection Package for CTX TC machines

- Avoiding tool breakage

- Increase in machine availability

- Damage reduction

- With interpolation turning, the tool cutter follows a circular movement, where the cutter is always oriented towards the center Of the circle.

- Possible for external and internal machining

- Synchronization and tool path controlled by the cycle

- NEW: in version 2.0 complex turning contours are possible (currently only available on the DMU 50, other machine types will follow)

- Easy manufacturing of sealing surfaces where milling operation might not be possible.

- Complete component processing in one clamping possible

- Reduced investment costs for tools

- Process-oriented adjustment of the feed rate n relation to the table loading

- Minimization of machining time with maximization of the component quality

- NEW: Now also available for CTX TC. Ideal machining result with the highest machine dynamics*

*without consideration of feed weight

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

Turning

- Measurement and correction of the position of turning and Pivot axes (C4, C3, B)

- Sag compensation possible

- Can be used in combination with standard probes from customers (recommended Renishaw, Blum)

Milling

- Toolkit for checking and correcting the kinematic accuracy of 4- and 5-axis machine configuration

- All head variations and table axes

- Reliable re-calibration of the machine before a highly precise processing

- Continuous documentation of machine accuracy

- No rejected parts due to unknown Geometric-deviations

- Periodic recalibration of the machine with comprehensive documentation

- Highest kinematic accuracy in self-regulation

- Measurement of webs and grooves on components

- Measurement of diameter in difficult to access places

- Available with manual and retractable Calibration unit Package content

- L-Measuring probe according to Customer-specific design

- Flexible application possibilities

- In process measurement

- Milling of oval and polygonal geometries

- Machining of excentric face polygons possible

- Simple selection of suitable machining strategies

- Simple parametric definition of the shaft-hub connection according to DIN 32711 and DIN 32712

- Enable the machining of small workpieces or those made of long-chipping materials. The perfect complement to Polygon / Oval-Turning.

Service & Training

Downloads & Technical Data

Special technical articles, analyses and background information on topics that move our industry.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://mydmgmori.com/

Thank you very much for your interest.

Please fill out the form below to download the requested document.

If you accept the storage of cookies, this form appears only once during your visit.