LASERTEC 125 DED hybrid

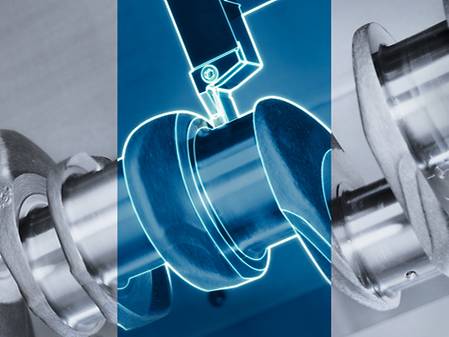

Directed energy deposition combined with 5-axis milling, for building and repairing of high-value metal parts

Max. X-axis stroke

53 in.

1,335 mm

Max. Y-axis stroke

49 in.

1,250 mm

Max. Z-axis stroke

35 in.

900 mm

Max. laser power

3,000 W

3,000 W

Max. workpiece weight

4,409 lbs.

2,000 kg

Highlights

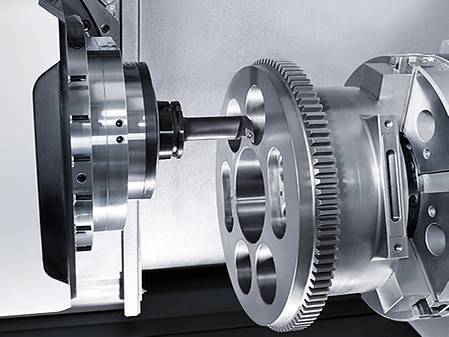

Proven monoBLOCK design for the best machine performance

- Fiber-guided diode laser with 3,000 W power and 600 µm fiber diameter

- Powerful motor spindles up to a maximum of 20,000 rpm

- NC swivel rotary table with swivel range A-axis: + 120 ° / -120, C-axis 360 ° endless, for up to 2,000 kg component weight

- Large door opening of 1,900 mm and unique access to the work area with minimal space requirements

- Comprehensive cooling measures, powerful cooling unit and multi-sensor compensation as standard

High flexibility of manufacturing processes by combining welding and milling on one machine for additive manufacture and repair

- The laser deposition head is handled by a fully automatic shuttle without manual intervention

- 5 axis material deposition by coaxial nozzle for homogeneous powder distribution, independent of direction of laser deposition welding

- Full 5-axis milling capability based on the monoBLOCK machine

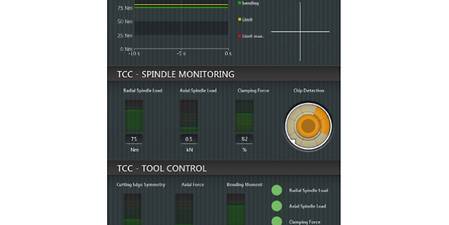

AM Assistant for the best process reliability and comprehensive traceability

- Integrated thermal imaging camera for observation of the whole working area, adapive process control and constant monitoring of the working distance

- Powder feed rate sensor as well as automatic powder calibration.

- AM Evaluator for visualisation of the relevant process data (e. g. meltpool size, powder mass flow) as a digital 3D-model as well as in the chronological sequence

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

- One software package for the complete process chain (design, additive process, substractive machining, finishing)

- Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine movements for collision prevention

- Change between additive and machining programming strategies all within one programming environment.

Using Multi-Materials and Gradient Materials for Improved Part Performance

- Selectively adding materials with more than 60 Rockwell to avoid heat treatment processes

- Improving cooling performance by using bronze material in the mould core

- Better materials and improved reliability in the repair process for increased service life

- Improved performance of exisitng tool designs by adding wear resistant coating

- Material gradients between hard and soft, magnetic and non-magnetic, etc.