Special Sales Promotion 2021

Take advantage of our promotions with special prices.

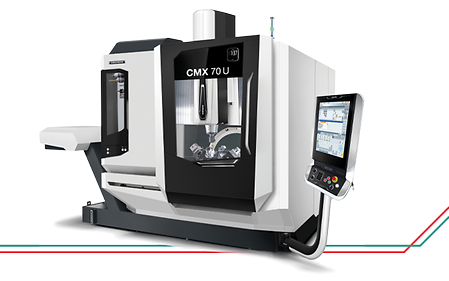

SPECIAL OFFER - CMX 70 U

HIGHLIGHTS

- 3D-control HEIDENHAIN TNC 620

- Production Package 1 with Chip Conveyor

- Tropical Package for standard spindle

- Tool Magazine 60 places SK40

- Touch Probe-Kit for HEIDENHAIN control

- 3D quickSET for CMX U

SPECIAL OFFER - DMU 75 monoBLOCK

HIGHLIGHTS

- CELOS with Heidenhain TNC 640

- Spindle taper HSK-A 63

- Production package 40 bar/23 l/min, 600 l tank

- Coolant ring jet

- Spray pistol for chip rinsing

- Cooling air blast

- Infrared measuring probe Heidenhain SK 40

- Tool measuring in machining area Blum Laser

- 3D quickSET

- Signal lamp 4-colour

- Tropical package (ambient temp. max. 50 °C)

- Electronic handwheel

- ATC (Application Tuning Cycle)

- Documentation 1 English

- Electric circuit diagram English

- 3D Data Model

SPECIAL OFFER - NLX 2500Y/700

HIGHLIGHTS

- Control M730UM with CELOS

- CELOS - ERGOline Touch

- (Spindle 1) Standard spindle 18.5/18.5/15 kW, 4,000min-1

- (Spindle 1) KITAGAWA 10in. Hollow Chuck BR10A821

- (Spindle 1) Hollow Cylinder set for KITAGAWA 10in. Hollow Chuck BR10A821 (without chuck body)

- Turret : Y-axis

- Rotary tool spindle 40/ 14 Nm, 10,000 min-1

- 12-station bolt-tightened turret (standard specification) (Y, SY, SMC)

- Overhang of O.D. cutting rotary tool: 100 mm (limited Y-axis travel)

- Tailstock spindle live center MT5 (STD)

- Usable Coolant Type: Water-Soluble Coolant

- Chip conveyor (right discharge, hinge type) (/500)(/700)

- High-pressure coolant system (800/ 1,100 W)

- Manual in-machine tool presetter (pivoting type) (STD)

- Signal lamp 4 colors (Red, yellow, green, blue)

- Workpiece unloader (built-in type)

- Interface for Bar feeder (LNS) (multiple)

- Transformer E30050 + Cable 55KVA

- Voltage of Customer Factory 415 V

- Frequency 50 Hz

- Setting Unit mm

- Alternating speed

- Interface for Input /Output (RS232C)

- Addition of optional block skip (soft key type 2-9)

- X-Axis Direction JIS / ISO Standard

SPECIAL OFFER - NLX 2500SY/700

HIGHLIGHTS

- Control M730UM with CELOS

- CELOS - ERGOline Touch

- (Spindle 1) Standard spindle 18.5/18.5/15 kW, 4,000min-1

- (Spindle 2) Standard spindle 11/7.5 kW, 6,000min-1

- (Spindle 1) KITAGAWA 10in. Hollow Chuck BR10A821

- (Spindle 1) Hollow Cylinder set for KITAGAWA 10in. Hollow Chuck BR10A821 (without chuck body)

- (Spindle 2) KITAGAWA 6in. Hollow Chuck BR06A521E

- (Spindle 2) Solid Cylinder set for KITAGAWA 6in. Hollow Chuck BR06A521E (without chuck body)

- Turret : Y-axis

- Rotary tool spindle 40/ 14 Nm, 10,000 min-1

- 12-station bolt-tightened turret (standard specification) (Y, SY, SMC)

- Overhang of O.D. cutting rotary tool: 100 mm (limited Y-axis travel)

- Usable Coolant Type: Water-Soluble Coolant

- Chip conveyor (right discharge, hinge type) (/500)(/700)

- High-pressure coolant system (800/ 1,100 W)

- Manual in-machine tool presetter (pivoting type) (STD)

- Manual in-machine tool presetter (removable type) (Spindle 2)

- Signal lamp 4 colors (Red, yellow, green, blue)

- Standard workpiece unloader (built-in type)

- Spindle 2 workpiece ejector

- Interface for Bar feeder (LNS) (multiple)

- Transformer E30050 + Cable 55KVA

- Voltage of Customer Factory 415 V

- Frequency 50 Hz

- Setting Unit mm

- Alternating speed

- Interface for Input /Output (RS232C)

- Addition of optional block skip (soft key type 2-9)

- X-Axis Direction JIS / ISO Standard

- T00184 O.D. cutting dual-tool holder 25 X 25

CONTACT INFORMATION

You can contact us by e-mail at aust.info@dmgmori.com or call:

0800 271 010 (from New Zealand)

1300 457 124 (from Australia)