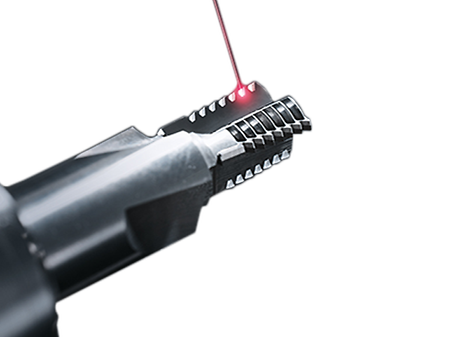

Laser diamond-tool machining with the LASERTEC PrecisionTool series

Laser processing of high-end precision tools

- Up to 210% faster and up to 56% lower cost per part compared to erosion machining

- Laser finishing of PCD, PCBN, CVD, MCD up to 3.0 mm/min.

- Complete machining incl. clearance angle, chip breakers

- Flexible automation systems for maximum productivity

- ERGOline 21.5" Multi Touch Panel with CELOS and SIEMENS SIMUNERIK 840 D sl

- Established software features - the easiest switch from eroding to laser processing!

Economical production of cutting edges and chip breakers in PCD

Applications for precision tools made from polycrystalline diamond (PKD) and cubic boron nitride (CBN) include machining non-ferrous metal alloys, hard metals, carbon fibers (CFRP), and ceramics. The tools are notable for their extreme hardness, which extends tool life by up to 40 percent. However, grinding them conventionally or manufacturing them by means of erosion is a high-effort enterprise. The LASERTEC PrecisionTool series from DMG MORI is the perfect alternative for the machining of cutting edges and chip-breaker geometries of reversible cutting inserts and rotary tools. Laser processing allows diamond tools to be machined economically, with a focus on quality.

This means that with laser technology, DMG MORI has been able to achieve a new level of quality in the processing of PCD tools. One of the impressive results of this is significantly lower cutting-edge chipping compared to ground or eroded tools. This non-contact and reliable method is also resource-efficient and sustainable, because it does not wear out grinding tools or require erosion wires.

Easy transition from erosion to laser machining

DMG MORI’s machine portfolio for laser machining PCD tools includes the LASERTEC 20 PrecisionTool with travel distances of 200 x 400 x 280 mm and the LASERTEC 50 PrecisionTool. Here, the travel distances are 500 x 500 x 700 mm, which enables machining of large tools with diameters up to 360 mm and lengths up to 420 mm. And in addition, the smaller model in its PreCut variant is suitable for the 5-axis separation of cutting inserts from blanks – a process ten times faster compared to wire cutting. The LASERSOFT software deploys the industry-standard (GTR) as a programming solution. This allows for the import of existing EDM projects, with a user-friendly interface that simplifies the transition from EDM to laser machining.

DMG MORI automates the processing of PCD tools, thus ensuring maximum productivity with minimal space requirements. With both LASERTEC PrecisionTool machines, space-saving pallet handling systems are available: the PH 10|100 for the LASERTEC 20 PrecisionTool and the PH 50 for the larger model.

Laser diamond-tool machining: a quick summary

What are PCD and CNB tools?

Due to their extreme hardness, tools made from polycrystalline diamond (PCD) or cubic boron nitride (CBN) are perfectly suited to precision machining hard metals, non-ferrous metal alloys, carbon fibres, and ceramics.

How are PCD tools manufactured?

Since conventional machining of PCD tools through grinding or erosion is highly labour-intensive, laser machining is an optimal solution for producing cutting edges, chip-breaker geometries of reversible cutting inserts, and tools.

What are the advantages of PCD tools?

Due to their hardness, PCD tools are highly durable and can process challenging materials including non-ferrous metal alloys, hard metals, carbon fibres (CFRP), and ceramics with extended tool life.