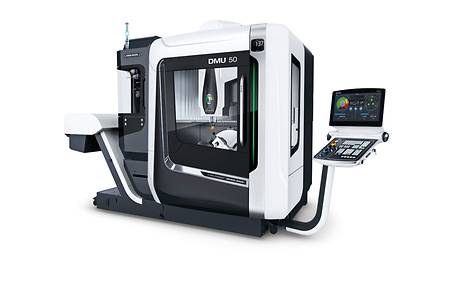

The original – now with distinctly enhanced technology for the 5-axis requirements of tomorrow

With its high-quality equipment the new DMU 50 3rd Generation convinces price-conscious users from demanding branches.

The DMU 50 combines more than 20 years of experience, proven technology and low investment costs in the 5-axis portfolio of DMG MORI. On this basis and enhanced in all respects the bestseller has moved into the next round. This compact DMU 50 3rd generation sets new standards in 5-sided to 5-axis simultaneous machining. With its extended swivel range, more powerful spindle and its innovative cooling concept the world premiere guarantees a competitive edge in a multitude of branches. Its areas of application range from training, to general mechanical engineering, jig construction and on to include applications in demanding branches such as the aerospace, medical and automotive industries.

While redeveloping the DMU 50 3rd Generation DMG MORI has managed to harmonize the modern appearance of the design with user-friendly operation. The large, smooth opening door to the work area, for example, with a width of 876 mm ensures unrestricted access from the front, even in combination with automation solutions. The table also has an ergonomic loading height of 800 mm. The optimum accessibility of the DMU 50 3rd Generation even encompasses maintenance components such as the control cabinet, fluid box, oil mist separator, heat exchanger and cooling unit.

Travel paths of 650 x 520 x 475 mm and workpiece weights of up to 300 kg mean the new DMU 50 3rd Generation covers a wide range of components. Its new NC swivel-rotary table with an enlarged swivel range of −35°/+110° boosts this versatility. A rapid traverse of 42 m/min and 30 rpm in the swivel-rotary axis ensure the dynamics for 5-sided to 5-axis simultaneous machining. In addition to the 15,000 rpm speedMASTER motor spindle, the user can also choose between motor spindles with up to a 20,000 rpm. Also available as an option is an expanded tool magazine with up to 120 pockets. There are 30 tool pockets in the standard version.

The DMU 50 3rd Generation achieves a unique degree of precision of less than 6 µm that is unbeatable in this segment thanks to its one-piece machine bed on the one hand and on the other its innovative cooling of the guides, drives and table bearings. Directly driven ball screws and direct path measuring systems in all five axes round off the equipment with regard to the machine’s high degree of precision. The DMU 50 3rd Generation can be expanded with coolant tanks and tool measurement as an option.

A 21.5” ERGOline with CELOS and Siemens 840D solutionline as well as a 19” ERGOline with HEIDENHAIN TNC 640 are available as modern control options. DMG MORI also has diverse automation solutions in its program for the DMU 50 3rd Generation, such as workpiece or pallet handling systems. This enables the world premiere to master challenging applications in the future-oriented aerospace, medical, automotive and energy branches – a demand that was already taken into account during the practice-oriented development of the machine. In other words, the DMU 50 3rd Generation continues to fulfil all the requirements that ensure it will remain DMG MORI’s bestselling 5-axis model.

Highlights DMU 50 3rd Generation

- 78 % larger work area

- 40 % higher rapid traverse speeds 42 m/min as standard

- 28 % greater swivel range, Swivel rotary table with -35° / +110°

- Experience gained from more than 10,000 machines already supplied

- 5-axis simultaneous machining as standard