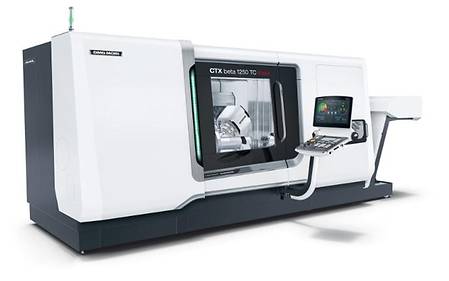

CTX beta 1250 TC with the new turn-mill spindle compactMASTER for a 170-m larger work envelope

Upgrade of the CTX Turn & Mill Centres of the 2nd generation for workpieces up to ø 500 mm and 1,210 mm turning length on 10.2 m2

For several decades, DMG MORI has been setting standards in the market of complex universal turning with its CTX series. A particularly far-reaching milestone here was the integration of a B-axis some years ago for the first time, thus extended the range of services of the at the time completely newly developed series to the turning/milling range. Today, the CTX range includes nine different sizes, based on which a total of 40 expansion options for workpieces of different sizes can be configured task-optimized. The CTX beta 1250 TC in its second generation now represents the most recent highlight of the innovative platform strategy of DMG MORI, which will celebrate its world premiere at the open house event in Pfronten.

With the CTX beta 1250 TC 2nd generation, DMG MORI expands its portfolio of Turn & Mill Centres once again within the CTX range. The CTX beta 1250 TC is designed for universal application in turn/mill machining of workpieces up to ø 500 mm and 1,210 mm turning length, whereby the Y-axis stroke, which has been increased by 50 mm to 250 mm, increases flexibility during off-centre machining. The feed rate which is increased by up to 65 % to max. 50 m/min ensures high productivity already as standard. The robust direct linear measuring systems from MAGNESCALE ensure highest precision in all three linear axes. Furthermore, the optional linear drive generates even more speed, dynamics and precision. The direct drive accelerates the Z-axis with 1g to up to 60 m/min with highest long-term precision, including a 5-year warranty on the direct drive.

Another core element of the new CTX beta 1250 TC is the fast B-axis in Direct Drive technology with a continuous swivel range of ±120°. However, the distinctive feature is the new turn/mill spindle compactMASTER. With a length of only 350 mm it generates a space gain of 170 mm, which has enabled machining of workpieces of up to 350 mm length with tools of up to 400 mm length. In the process itself, the new compactMASTER spindle with HSK-A63 interface (optional Capto C6) provides an rpm of 12,000 rpm, a torque of 120 Nm as well as a performance of 22 kW. A 20,000 rpm high-speed version is also available as an option. Meanwhile, the generously dimensioned 70 mm diameter spindle bearing of the compactMASTER ensures stability and precision in interaction with the temperature-stabilising sleeve cooling.

The CTX beta 1250 is equipped with a disk magazine with 24 pockets as standard. Optionally, a 48- and an 80-pocket chain magazine are available. The machine’s range of applications can thus be considerably increased, particularly for a range of components that are frequently changing - either due to the reduction in tooling times or due to the option of targeted usage of sister tools.

To take account of the increasing energy prices, the new CTX beta 1250 TC of the second generation is equipped with a large number of energy-saving features. A cooling unit with added water, an energy-efficient control cabinet cooling unit, synchronous motors for higher acceleration rates and reduced energy consumption, as well as hydraulic inverter units reduce energy consumption by more than 25 %.

The CTX beta 1250 TC is equipped with the latest 3D control technology. The standard version comes with CELOS by DMG MORI with 21.5” ERGOline control and SIEMENS. CELOS provides a uniform user interface for all new high-tech machines from DMG MORI. A unique 21.5” multi-touch screen displays all CELOS APPs, which provide the user with integrated management, documentation and visualisation of order, process and machine data. Additionally, machine operation is simplified, standardised and automated. Optionally, the machine can be equipped with Operate 4.5 on SIEMENS 840D solutionline including 19“ ERGOline.

In both cases, the standard version of CTX beta 1250 TC already impresses with ShopTurn 3G for workshop-oriented programming. Complete flexibility between DIN and workshop-oriented programming is guaranteed by the DIN / ISO interface. A combination of ShopTurn cycles with DIN functions is also possible. Possible applications of the CTX beta 1250 TC are rounded off by exclusive technology cycles that are available as an option.

Based on a simple and dialog-supported input of the required parameters, the machining functions for off-centre turning and milling, for example, can be generated as well as special threads with the multi-thread cycle, and all this without a CAD/CAM system. Furthermore, a tool sorting cycle is available, which reduces idle times by sorting the tools in the chain magazine according to their call parameters. In total, based on the innovative technology cycles, up to 60 % of programming time can be saved.

“The success of our Turn & Mill machines is also the result of fast and simple programming. In addition to the standard options provided by the Shop Turn 3G controller, our exclusive technology cycles mentioned above also accelerate the process. This makes the CTX TC series a profitable alternative for a growing number of users compared to sequential machining on different machines,” believes Harry Junger as Managing Director of GILDEMEISTER Drehmaschinen GmbH.

Highlights of the CTX beta 1250 TC

- compactMASTER: Ultra-compact turning-milling spindle for minimum space requirement in work area with 20 % higher torque, HSK-A63 (Capto* C6), 12,000 rpm, 22 kW and 120 Nm, high-speed design with 20,000* rpm

- 170 mm space gain thanks to new B-axis: horizontal through-drilling or boring of 350 mm long workpieces, tools up to max. 400 mm length

- Up to 65% higher feed rate resulting in higher dynamics, max. 50 m/min (X / Y / Z = 40 / 40 / 50 m/min)

- 1 g acceleration and 60 m/min feed with linear drive* in the Z-axis with highest permanent precision and 5 years warranty for the linear drive

- 50 mm larger Y-stroke (250 mm) for more flexibility for off-centre machining

- State-of-the-art 3D control technology: CELOS from DMG MORI with 21.5“ ERGOline Control and SIEMENS

- 5-axis simultaneous machining (in connection with technology cycle*) via B-axis with Direct Drive technology

* optional