AMB 2016 - Robo2Go

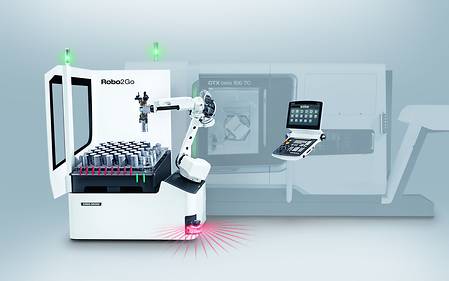

DMG MORI will present Robo2Go, a mobile automation system for turning centers with the simplest of programming via a CELOS APP

Automation can really be so simple

At the trade show AMB, DMG MORI will be presenting the exemplary implementation of an automated process chain from the web shop to the finished workpiece. The core of the integrated turning cell is the new loading and unloading system Robo2Go. Designed for mobile use on up to four turning centers, Robo2Go is controlled via a special CELOS APP in which only a few entries are needed and a particular knowledge of robots is not required.

Thanks to the use of robotic technology, investment costs in the field of automation have dropped drastically in the past few years, turning the attention of small and medium-sized enterprises more and more to the indisputable quality and cost benefits that such technology has to offer. Nevertheless, a degree of reluctance was noticeable in this customer segment. Partly due to a lack of knowhow in programming on the one hand; and doubt that the robot would be used to full capacity on the other. This caused those, who might have otherwise been interested, to feel it was too much of a risk. DMG MORI has now overcome this obstacle in one innovative leap with its newly developed Robo2Go.

The Robo2Go system is unsurpassed because of its flexibility. It can be used on up to four turning centers if required with the aid of a lifting device, which maximizes investment security. In addition, the system can be set up on the control panel with just a few entries, which in turn minimizes tooling times and therefore optimizes utilization rates.

All in all Robo2Go gives users a clear competitive advantage. “What makes it so special is that the robot is not programmed via the Fanuc teach pendant”, explains Jürgen Groß, Managing Director Sales at DMG MORI Systems. This takes place via a special Robo2Go APP from the DMG MORI graphic control and operation system CELOS. The operator needs no prior knowledge of robots, because once configured by DMG MORI Service the robot operates completely parameter-based via CELOS. In other words: all the operator has to do is enter the dimensions of the workpiece, chuck and gripper, then select one of the pre-defined arrangements of the workpiece tray and lastly start the automatic process. “This innovative way of programming a robot enables especially smaller firms entry into flexible automation without the need of any expert knowledge,” Silvio Krüger, Managing Director Operations at DMG MORI Systems, went on to tell us.

Economical entry into automation

In comparison to other automation solutions that DMG MORI has long offered, Robo2Go allows for a very cost-effective entry into automation. The technical solution differs from standard automations in terms of its barrier-free safety technology. The use of an area scanner means that Robo2Go can do without protective fences. Instead the system stops as soon as a worker enters the defined stop area. A faster working speed for the robot is possible because this is not a collective solution in which the human operator works in the action area at the same time as the robot.

Robo2Go is designed to handle a wide range of parts. For this reason, the robot is available with load capacities of 10 kg, 20 kg and 35 kg. The weights of workpieces in the case of a single grip – whereby the gripper can be adjusted without tools – are 5 kg, 12 kg and 22 kg. Workpiece diameters are between 25 and 125 mm and lengths from 50 to 250 mm. The workpiece tray can be loaded with weights of up to 700 kg, which adds up to a maximum capacity of 210 workpieces depending on diameters.