Additive Manufacturing has revolutionised metalworking

Infinite options

- Conformal channels offer revolutionary cooling options, e.g. for injection mould tools, minimising production cycles.

- Integrated channels reduce heat load of highly stressed guide vanes in engine combustion chambers. This maximises efficiency and reduces fuel consumption.

- Additive methods for producing crowns and bridges are already being used in dental technology.

- Even the most complex hydraulic or pneumatic valves can be created flexibly with the minimum use of material.

- Functional prototypes can be built overnight using series production materials. Development times are reduced by weeks or even months.

If there were any questions whether additive manufacturing in the metal sector could achieve the leap into industrial implementation, any doubts were answered at Formnext in November 2017. The future is almost within reach – also thanks to DMG MORI!

Various providers exhibited new machines and concepts at the fair in Frankfurt, in particular trendsetting machines and exhibits for future manufacturing. What also became clear when walking through the fair halls: as one of just a few manufacturers in this field, DMG MORI presented visitors with a large spectrum of options for further expansion of additive manufacturing.

As an additive pioneer, the company used integrated process chains to show manufacturers its process competence with both powder bed and powder nozzle technology. The starting point for this additive revolution is an extremely fine powder material with grain diameters of just a few μm.

Additive Manufacturing made by DMG MORI

With regard to systems, DMG MORI offers customers from one source two of the most significant current additive manufacturing methods for metal components. These methods have three continuous process chains, each based on machine technology and software, for powder bed and powder nozzle respectively.

- Agile product development - Product development is sustainably accelerated through the digital process chain from design to production

- Tool-less production - This production method enables significant reduction of production costs and time

- Functional integration - The increased surface area leads to improved cooling of the component

- Complex geometries - Sharp transitions, awkward features and negative angles can be produced that are almost impossible to achieve in any other way

- Work preparation - Optimal interaction of parameter optimisation and machine with the in-house developed RDesigner

- Integral design - This new design brings together 22 conventional components, seals and connectors

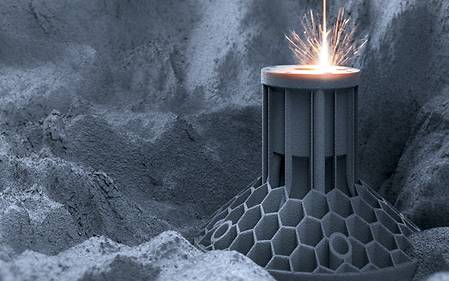

- Lightweight construction - Integrated honeycomb structure enables significant reduction of component weight while component stiffness remains almost unchanged

- Functional integration - Complex internal channels can be created to carry coolant and process gases, for example

LASERTEC 30 SLM - Patented for best quality

Highlights

- Additive manufacturing with 300 × 300 × 300 mm build volume

- Application-specific fibre laser sources from 400 Watts to 1 Kilowatt

- High precision building of 3D parts with layer thicknesses between 20 and 100 μm

- Minimal operating costs: only 70 l/h argon consumption

- Integrated powder recycling for even more efficiency and improved powder handling

- Faster powder change with exchangeable powder modules

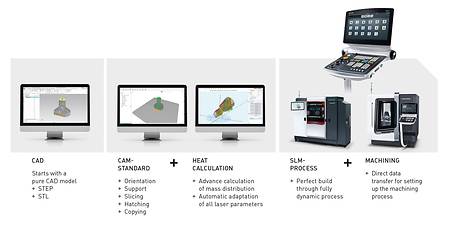

- Complete software solution with CELOS SLM from CAD file (RDesigner) to process control with a standardised user interface

- Optimal process chain with post processing on DMG MORI HSC or DMU milling machines for absolute component accuracy and perfect surfaces

Control - Workflow SLM technology – Progress of digitization

LASERTEC 3D hybrid: Finished part quality in one setup

DMG MORI successfully entered the market four years ago with machines in the LASERTEC 3D hybrid series, which combine laser deposition welding and subtractive machining. This concept is used both in the LASERTEC 65 3D hybrid with additional 5-axis milling and in the LASERTEC 4300 3D hybrid combining laser deposition welding and 6-axis turning/milling. Both machines are designed for manufacturing comparatively large parts such as complex turbine components.

Additive team player for the manufacturing industry

DMG MORI has now uniquely upgraded its portfolio with these LASERTEC 3D hybrid machines, developing a complete range for additive manufacturing. While the LASERTEC 65 3D has been designed for pure laser deposition welding of larger parts, the LASERTEC SLM series has expanded the product range for the powder bed method using selective laser melting. As additive team players, these two innovations combined with high-tech machines in the DMG MORI machining portfolio offer numerous options for full industrial processing.

LASERTEC SLM: Revolutionary powder machine

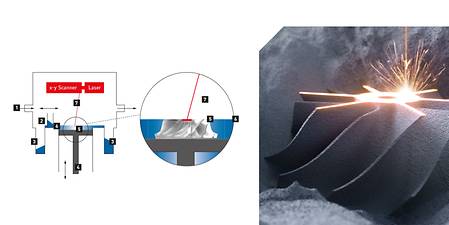

The LASERTEC SLM machines are the current highlight. In the powder bed method, a thin layer of powder is applied to a lowering platform. A continuous laser beam then melts the applied powder at the programmed positions in a cycle time of 10 μs.

Once all positions in one layer have been processed, the platform lowers according to the required layer thickness (between 20 and 100 μm). This process is repeated until the component has been fully built. When the completed workpiece is released from the powder bed, any excess powder falls through a mesh into a container for reuse.

SLM principle - Powder bed functional principle

- Inert gas (argon)

- Recoaters

- Powder containers

- Lowering work platform

- SLM component

- Powder bed

- Laser beam

Holistic software solution for the powder bed method

DMG MORI is also offering a comprehensive software solution with CELOS SLM for CAM programming and machine control in one package and with a standardised user interface. The tailored and standardised user interface can be used to program components – irrespective of their complexity – with minimum outlay and transfer the data immediately to the machine. Minor modifications can be made without retrograde steps and with the same user convenience directly on the machine control.

At the control level, CELOS SLM offers an adaptive exposure strategy that is automatically generated before the process starts. It ensures that the energy input into the component is so precisely controlled that no energy is wasted during the entire build process at scanning rates of approx. 20μs. All process- relevant parameters such as scanning speed, laser output and focus diameter are included in the programming process. Deformation and stress generation in the material are therefore prevented and even very thin horizontal or vertical walls can be safely generated.

Quick-change module for powder change

A new powder module provides flexibility for order planning and high usage rates of the LASERTEC SLM systems. When changing materials, the work area must be carefully cleaned after the powder module has been undocked and docked so as to prevent entry of foreign material into the closed powder circuit. This has reduced changeover intervals between 2 powders from approximately 1.5 days to around 2 hours today and enables economic processing of different materials.

Powder module - Change of materials without contamination in less than 2 hours

Innovative powder handling system for material change in less than two hours:

- Cleaning the work area to avoid entry of foreign material

- Insert and dock the new powder module

- Start the LASERTEC 30 SLM

Manufacturer-independent material selection

- AlSi 10 Mg 0.5

- CoCrMo (ASTM F75) for implants

- CoCrMo for dental prostheses

- Inconel 625

- Stainless steel 1.4404 (316L)

- Titanium TILOP

- Tool steel 1.2709

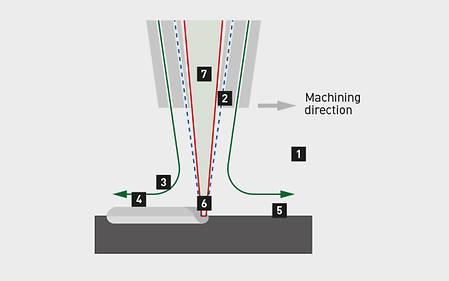

Powder Nozzle

Laser deposition welding 3D / 3D hybrid

- Manufacture of larger workpieces:

- LASERTEC 65 3D: ø 650 × 560 mm

- LASERTEC 65 3D hybrid: ø 500 × 400 mm

- LASERTEC 4300 3D hybrid: ø 660 × 1,500 mm

- High build rate, averaging 750 g/h (steel, 90 cm³/h, LASERTEC 65 3D)

- Build layer, approx. 0.8 – 1.5 mm

- Multi-materials and machining existing workpieces:

- Repair

- Coating

- Prototyping / manufacture

- Inert gas

- Powder

- Applied material

- Connection zone

- Workpiece

- Weld pool

- Laser beam

Example of multi-materials: Drill bit / oil industry (ø 150 × 160 mm)

- Stainless steel

- Inconel

- Tungsten carbide