Service performance assures machine availability

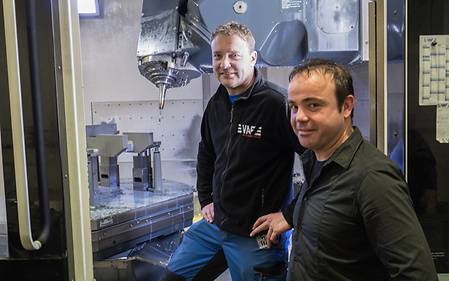

VAF GmbH has been using machine tools from DMG MORI for 20 years now – a long-term cooperation even where service is concerned.

Car manufactures boost their sales with shorter development cycles and faster introduction of new vehicle models. This growth also has a direct impact on their suppliers and service providers, as the development of VAF GmbH clearly shows. Since its foundation in the year 1983, the company from Bopfingen has established itself as a renowned supplier for the automotive industry with individually developed assembly lines for vehicle gearboxes and engines. Around 360 employees develop and build the special complex machines. Where machining is concerned, VAF meets the high demands on quality and efficiency in production with nigh on 30 machine tools from DMG MORI – including a number of 5-axis machining centres. The high degree of reliability of this machine park is also a result of the close cooperation on the service level.

“Reliable products and on-time deliveries are the only way to encounter the enormous competitive pressure that prevails in the automotive industry”, says Production Manager Mike Göggerle about the challenges in day-to-day business. It takes the team about nine months to develop and construct application-specific assembly lines. These are used for assembling up to 2,400 gearboxes a day, for example. The need for high capacity utilisation in production is something VAF has in common with the car manufacturers. “We can only meet delivery deadlines if we work at maximum productivity.”

Flexibility thanks to the diverse machine park

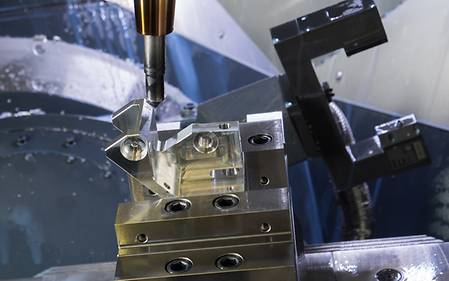

VAF ensures efficient and productive machining of the many workpieces with the almost 30 machine tools from DMG MORI in its machine park. “The high degree of complexity and individual production require a high level of machining diversity and flexibility”, explains Mike Göggerle. Two DMU 60 eVo linear machines are among the company’s latest acquisitions in the field of 5-axis machining centres – both with a pallet handling automation. In turning, too, the trend is moving towards complete machining. In 2016, for example, a CTX beta 1250 TC was installed.

At VAF innovative CNC technology is even used during the training phase, with young trainees being involved in the day-to-day business at an early stage. There are two modern DMU 50 machines for 5-axis machining and an NEF 400 in the training workshop. The CELOS APP-based control interface is another step towards the future claims Mike Göggerle: “Its intuitive operation simplifies the handling of the complex machines enormously.” In particular the availability of digital data and manuals is a great help to the trainees.

Solution-oriented support provided by the telephone hotline

However, for Mike Göggerle the efficiently of the CNC machines is only one side of the coin: “The reliability of the machine park is just as crucial.” VAF works proactively to ensure a high level of machine availability with its own maintenance team and in close cooperation with the Service Department of DMG MORI. Mike Göggerle sees very different factors that have to be observed: “First of all we ensure that our maintenance technicians are always up-to-date and can respond quickly by sending them regularly to DMG MORI training sessions.” This means they can quickly resolve any technical issues independently or with the support of the telephone hotline. “As we document any problems very exactly and send the reports to DMG MORI, the hotline technicians are always well prepared in such situations.”

Short response times and fast spare part delivery

Of course cases still arise where the service technicians of the machine tool manufacturer have to come on site to solve a problem, says Mike Göggerle: “Our experience in such cases is the same as with the hotline – short response times – because DMG MORI has successively increased the number of specialists working in its Service Department. In addition the flat call-out rate and best-price guarantee for original spare parts also have a positive impact on the service costs.

Thanks to its large stocks DMG MORI has long been able to guarantee 24-hour delivery of spare parts. The spindle service is also held in high regard. “We only ever use replacement spindles from DMG MORI if a spindle is defect”, explains Mike Göggerle. In urgent cases the Spindle Service can deliver replacement spindles immediately, although a spindle repair within six days is also possible.

Prevention of downtimes through predictive service

For all the competence of the in-house maintenance team and fast response of the DMG MORI Service, Mike Göggerle nevertheless refers to predictive servicing and repairs: “Ideally no unscheduled standstill should ever occur.” Based on the machine data or on experience it is possible to nip many future problems in the bud. The rotary table and Y-axis of a DMC 200 U machine were recently replaced, for example, ensuring the availability of the machining centre again over a long period of time.

As VAF installs assembly lines itself and is therefore regularly confronted with service issues, Mike Göggerle is well acquainted with the tasks and obstacles this involves: “It is a great challenge for manufacturers to be ready with support and help for its customers anywhere and anytime.” The machine tool manufacturer’s consistent optimisation of its service offer in recent years clearly shows just how seriously DMG MORI takes this topic. “That is why I am convinced the service performance will continue to increase.”