Future-proof production with 5-axis machining

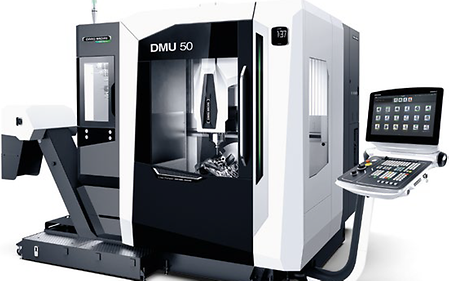

RX Industries (RXI) from Hilton Head Island, South Carolina, was founded in 2020 amid the apex of the COVID-19 pandemic as a manufacturing service of medical and industrial components as well as light assemblies. Focusing on the delivery of high quality results in both products and experiences to its customers, RXI implemented stateof- the-art CAM software and CNC machinery. They started out with 3-axis milling and discovered soon the opportunities of 5-axis simultaneous machining. Looking for the right machine tool they purchased a DMU 50 3rd Generation from DMG MORI.

Providing ISO standard practices RXI targets customers who are leaving their current suppliers because they need a curated experience of a solid CNC shop that “runs on best-practices for time tracking, order fulfillment, chain-of-custody, ITAR compliance, detailed QC reports and price competitiveness,” as Tom Rougeux, founder and owner of RX Industries, puts it. “We know in excruciating detail every aspect of our costs, and as a result, can control most of those without sacrificing a Level 10 experience back to the customer.” Using 3-axis milling from the start, RXI soon started looking for more productive machining technologies in order to increase their efficiency and competitiveness. “5-axis machining was and is the right way for us,” Tom Rougeux says. “After implementing ProShop ERP and MasterCAM in 2021 for multi axis CAM programming as well as SolidBox Engineering computers we went shopping for the right CNC machine to convey our brand to our customers.”

Professional service during the whole purchase

In an effort to find the right CNC machine tool for this corporate mission RXI interviewed multiple companies, went on a half-dozen field trips, and asked customers as well as vendors. “We sought a CNC that would articulate the trajectory of our new company to our customers in a way that would make us stand out from the purchasers of high volume/low price suppliers,” Tom Rougeux remembers. “We are looking for complex geometries with tighter-than-typical tolerances to showcase our expertise.” RXI was successful when they determined the DMU 50 from DMG MORI as the right choice.

Looking back to the purchase Tom Rougeux was satisfied with the professional service: “The DMG MORI team was exceptional in their care, professionalism and enthusiasm.” Every commitment made was fulfilled. “I have a very low tolerance for delays and wasted time and I was very pleased that the DMG MORI technical and sales staff met me exactly where I needed to be, when I needed to be there.

Perfect size for demanding medical and aerospace parts

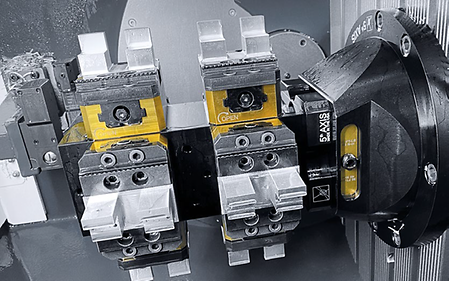

In the 5-axis universal machining center Tom Rougeux sees a great support for manufacturing complex smaller parts in medium-sized part lots: “RXI has a target size of not greater than 8.5 × 11 × 11 in. tall – a sheet of standard paper.” With travel paths of 25.6 × 20.5 × 18.7 in. (650 × 520 × 475 mm) and a table load of 661 lbs (300 kg) the DMU 50 3rd Generation fits perfectly well to this portfolio of parts. Additionally, the 5-axis capabilities were absolutely convincing. “The swivel area of the B-axis with -35° / +110° offers highest flexibility and the cooled table bearings guarantee highest precision,” Tom Rougeux adds. “So far we have made surgical lasers and are tooling up for aerospace instrumentation for a launch in the very near future. We also expect to be doing aircraft electrical connectors and orthopedic surgical tools. In terms of ergonomics the DMU 50 3rd Generation made a point with excellent visibility and accessibility. The tool magazine, for instance, can be loaded from the front even during machining. According to Tom Rougeux the CELOS control is another highlight: “In comparison to 1980’s looking controls of the competitors, CELOS is a sleek, user-friendly operator interface, which was far more intuitive and easier to learn than the various, legacy-type front-ends of the others.” Additionally, DMG MORI made financing very quick and easy. “While other companies were still gathering information, DMG had already come back with the answer for our financing, which, in the end, was just as competitive as everyone else.”

Heading towards a semi-autonomous future

Altogether, the DMU 50 3rd Generation turned out to be the best choice of several options RXI had when looking for the 5-axis machining center. “The others may have been substantially less cost, but the machine tool’s quality, design language, and DMG MORI’s expertise really made for an easy choice,” Tom Rougeux explains. He is convinced: “The DMU 50 3rd Generation is one more chapter in our story.” He says that 5-axis machining as well as assembling components gave RXI the opportunity to offer a holistic service in CNC manufacturing. He is already considering the next chapter with eight machines running in semi-autonomous fashion in five years: “Going forward, we plan to have 6-axis robot tending and the most advanced automatic assembly systems in the world on our little island.”

DMU 50 3rd GENERATION

5-AXIS EXCELLENCE ALLROUNDER – CNC UNIVERSAL MILLING MACHINE

HIGHLIGHTS

- 5-Axis Machining with up to 20,000 rpm

- Swivel Rotary Table for 5-Axes Simultaneous Machining

- Highest accuracy thanks to direct drives and the integrated cooling concept

- Innovative technology and top-class options for any application

- CELOS – APP-based user interface with access to all production-related information

RX INDUSTRIES FACTS

- Founded on Hilton Head Island, South Carolina, USA, in 2020

- 2.5 employees – 2 full time, 1 part time

- Manufacturer of medical, surgical, and industrial laser and electronic components in general industry

- Specialist in tight tolerance, small parts of aluminum, titanium, and stainless

RX Industries

386 Spanish Wells Rd., Bldg C-6

Hilton Head Island SC 29926

www.rxind.com

Contact us for all issues related to DMG MORI technical press.