Highly Productive 5-Axis Machining in 24 Hour Operation

Nabeya Co., Ltd. is headquartered in Gifu City (Japan, Gifu prefecture) and was founded in 1560 in the midst of the Sengoku period in Japan, the time of warring states.

During one of the most notorious battles – the Battle of Okehazama – the ancestors of President Tomohiko Okamoto were granted permission by the emperor to found the family company specializing in casting production. Today, Nabeya continues this tradition, employs around 200 people and dedicates itself to technological innovation. The company uses cutting-edge technology from DMG MORI to manufacture vibration isolators for semiconductor manufacturing equipment and surface plates for precision testing under the widely distributed ERON brand. The design, machining, assembly and inspection of these industrial components are carried out in-house.

Automation and 5-axis machining to combat the lack of skilled workers

“The same is probably true for other manufacturers, but our company is facing the growing challenge that qualified engineers are becoming ever scarcer. This has led to a lack of personnel who are able to manage complex processes with conventional vertical and horizontal machining centers,” explains Managing Director Shoichi Sakai. “My idea was to integrate the processes as much as possible to simplify process design and to implement automation and unmanned production at night at the same time. 5-axis machines are the perfect solution for this! I wanted to combine 5-axis machines and automation to reduce process steps, improve productivity and enable continuous 24-hour production.”

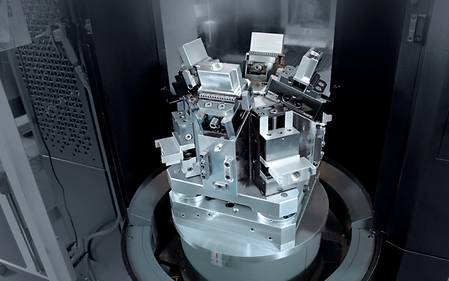

Last year, Nabeya introduced the 5-axis DMU 50 3rd Generation machine and the MATRIS robot automation system with a rack for 20 pallets at their main plant in Motosu, Gifu. The system is being used for the production of machine vices – Nabeya’s main product – as well as clamping units and other similar products. Only one operator is required to operate the automation system. The MATRIS system automatically processes all pallets. Various clamping elements can be used on the pallets during the process as well as different workpieces, depending on the fixture. In the past, the operator had to adjust every fixture for every type of workpiece. Thanks to MATRIS, only minimal setup is required as it can handle different workpieces and fixtures on each pallet for 5-axis machining on the DMU 50 3rd Generation.

Use of their own clamping materials

What makes this automation system so unique is the use of Nabeya's own fixtures, base elements, pallets and robot grippers. Their fixtures make it possible to clamp more than eight workpieces on one base plate, which can be automatically machined and measured on all sides in the 5-axis machine without retooling. The introduction of this automation solution in combination with in-house products enabled Nabeya to automate its varied production of small batch sizes and achieve highly precise, unmanned production during the night.

Increased productivity thanks to unmanned night shifts

“The work that used to take four people can today be done by just one operator. We only need to set up the workpieces during the day and the system automatically takes care of the rest during the night. All the workpieces are finished by the time we arrive at the factory in the morning. This means that our productivity has been considerably increased and it is much easier to plan our manufacturing,” says Factory Director Tomoaki Masuda. It is important when using automation like this that the system runs as reliably as possible. Tomoaki Masuda explains the reason for the successful operation: “Our system runs without any problems at all, thanks to the in-depth advice and troubleshooting provided by DMG MORI. For example, their engineers helped us to avoid downtimes caused by incorrect timing when exchanging the pallets or an accumulation of chips.”

From ten process steps to one

Shoichi Sakai reveals Nabeya’s future plans: “It was the first time that we introduced a 5-axis machine into our production and the positive effects could be felt immediately: The eight to ten work steps that used to be required can now be reduced to just one or two.” In addition, Nabeya is able to use its own fixtures and clamping systems in this automation system. This makes it the perfect showcase for its customers at the same time. “We would also like to show this automation solution to other manufacturers that are battling a lack of skilled labor and automating high-mix, low-volume production – and to support them in increasing their production efficiency.”

Nabeya Co., Ltd.

Wakasugicho 25, Gifu City

Gifu 500–8743, Japan

https://eng.nabeya.co.jp