Productive Mold construction thanks to modern CNC technology

DMG MORI machine tools and controls from HEIDENHAIN guarantee high quality and short machining times at KOSME in the production of stretch blow Molds

Since 1989 the Austrian company KOSME Gesellschaft mbH, which is based in Sollenau near Vienna, has been active in the field of labelling and filling technology. With the triumphant advance of PET bottles the company expanded its portfolio in the 1990s to include stretch blow machines – today its main focus. KOSME also produces the blow moulds it needs for this in Sollenau, for both its own stretch blow machines and those of its parent company. Since 2005 the company has been a daughter of Krones AG. 25 of its 135 employees are charged with the construction, programming, manufacturing and quality control in mould construction. Where machining is concerned the team has trusted in machine tools from DMG MORI and controls from HEIDENHAIN for many years now. The machine park includes among others nine universal machines from the DMU eVo linear series and three monoBLOCK machining centres. While the DMU eVo 60 linear machines in particular are equipped identically with iTNC 530 controls, KOSME opted for the new TNC 640 from HEIDENHAIN for its recently purchased DMU 95 monoBLOCK.

Over 3,000 blow moulds a year and small batch sizes of maximum 25 pieces are typical for mould construction at KOSME. Productive operation is essential here if a company is to remain competitive. Andreas Steidl, Head of Mould Construction, reveals part of the solution: “Our machines are in operation round the clock.” They normally work in a single shift, but “Automation solutions and machining times of several hours enable production to run at high capacity.”

Minimising throughput times with HEIDENHAIN on DMG MORI

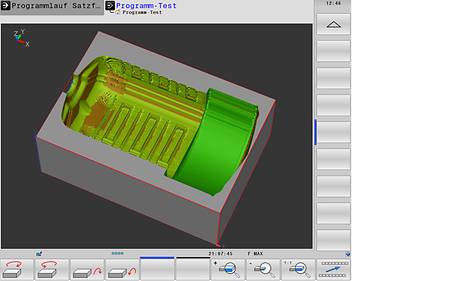

The company’s consistent machining and control philosophy also contributes to productivity. The machining centres are all equipped with controls from HEIDENHAIN, mostly with the iTNC 530 to date. “This means we can setup on one DMU 60 eVo linear and then continue machining on the identically equipped machines in parallel in order to minimise our throughput times”, explains Andreas Steidl. Although the latest purchases in the eVo field were still equipped with the iTNC 530 for exactly this reason, where the DMU 95 monoBLOCK installed in 2016 was concerned KOSME opted for the new TNC 640 from HEIDENHAIN. The attractive price of the pack machine from DMG MORI was a decisive aspect for KOSME plus the fact that it offered the space required for blow moulds with volumes up to 30 litres.“With regard to the control we have familiar dialog programming in HEIDENHAIN plain text on the one hand and a significantly expanded range of functions on the other that we can integrate in our work”, says Andreas Steidl about the TNC 640. Alone the enhanced programme simulation is a great benefit for workshop-orientated programming.

Improved surface qualities thanks to Advanced Dynamic Prediction

The strengths of the control really come into play where 5-axis machining with a swivel head and rotary table is concerned. With its Advanced Dynamic Prediction (ADP) feature, for example, HEIDENHAIM has optimised motion control even further. This applies in particular in the case of NC programmes generated on CAM systems. It happens quite often that only 3D models of poor data quality are available. This results in reduced data resolution or fluctuating distribution of points in the NC programme. ADP expands the conventional look-ahead of the permissible maximum feed rate and permits optimised motion control of the feed axes. This enables further optimisation of axis speed and acceleration in 3 and 5-axis milling and eliminates feed fluctuations arising from uneven distribution of points. The results are clean surfaces and perfect contours with the shortest possible machining times.

Reduced subsequent machining with HSC

While the DMU 95 monoBLOCK is designed especially for large workpieces, KOSME manufactures blow moulds for PET bottles down to volumes of 0.05 litres on the DMU eVo linear machines. Such a highly diverse range of moulds has come about not least due to the takeover by Krones AG. Andreas Steidl goes on: “With its takeover of KOSME Krones has expediently expanded it product range and generated synergies for both companies.”

The runtimes of the different blow moulds vary according to size and complexity of the future bottles from 60 minutes to over ten hours. “They high dynamics of the linear drives on the eVo machines prove very beneficial where such diversity is concerned. In combination with the HSC spindles excellent machining results can be achieved on the universal machines. “All moulds undergo final polishing, but with milling speeds of 40,000 rpm we can significantly reduce the time and effort required for subsequent machining.”

As a growth-orientated company KOSME always remains technologically up-to-date. Such an approach entails regular investments in modern CNC machines as well as the use of innovative control technologies. This goes without saying for Andreas Steidl: “It is the only way for us to keep up with the positive development on the market for PET bottles in the long-term as one of the leading competitors.”