The first industrial revolution marked a profound upheaval in business and society. Production technology and production processes began to evolve at previously unseen speeds, constantly overcoming new frontiers of possibility. Since then, groundbreaking technological innovations have again triggered new industrial revolutions, which have also had far-reaching consequences for the economy and society. Today, we are once again in the midst of such a transformation with new potential for industrial value creation.

The history of industrial production

The industrial landscape as we know it today began in the 18th century. Groundbreaking inventions and their use in the world's factories have shaped the history of industrial progress ever since. Then as now, new technological developments determined industrial production and changed it, in some cases rapidly. Centuries stand between the first revolution in the 18th century and today's fourth industrial revolution. Years in which production shifted from simple manufactories to ever more complex factories and ever more global value chains. With Industry 4.0 and the so-called fourth industrial revolution, a transformation is currently taking place that will once again significantly change industry.

From manufactory to industrial production

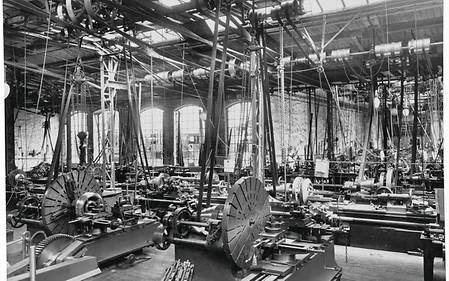

The first industrial revolution was triggered by groundbreaking innovations in the second half of the 18th century. At the center of these were inventions such as the mechanical loom – machines powered by water and later steam power. Their spread displaced the previously widespread manufacturing in manufactories and made mass production possible, the basis for “industrial production” in factories.

In contrast to manufactories and handicraft businesses, these new industrially producing companies henceforth focused on the procurement and further processing of raw materials as well as semi-finished products for the production of goods in large quantities. This was characterized by a high degree of division of labor between man and machine and a concomitant reduction in the complexity of the individual work steps. The resulting sharp increase in demand for labor also had a massive structural impact on the prevailing economy. The transformation from an agrarian economy to one dominated by industry had begun.

Factory organization 2.0 – the second industrial revolution

A key technological driver of the second industrial revolution was the dynamoelectric principle discovered by Werner von Siemens. The dynamo machine, presented in 1866, formed the basis of later powerful electric motors. The widespread electrification of factories and the move away from steam engines as a drive technology unleashed new potential.

The factory layout was no longer linked to the steam engine as the central drive, but could be adapted and optimized through the use of electric power, also from the point of view of optimum material flow. The principle of assembly line production introduced by Henry Ford in automobile manufacturing took advantage of the new possibilities and was fundamentally based on factory electrification.

The heyday of this second industrial revolution can be dated to the 1920s. Driven by dynamic development, the degree of division of labor and the rationalization of manufacturing processes also continued to increase, resulting in gains in effectiveness and efficiency for manufacturing companies.

Information technology meets production technology: the third industrial revolution

Around 50 years later, in the 1970s, a third industrial revolution brought major innovations to manufacturing companies. The impetus came from advances in microelectronics and computer technology. Over time, this led to the emergence of computer-controlled and automated factories. In addition to a further increase in the division of labor and the use of manufacturing robots in routine activities, this revolution is characterized by a steadily advancing structural change. A growing influence of information technology and an increasing internationalization of customer and supplier relationships have since determined industrial production.

The digital future of industry

At the heart of the transformation currently underway to what is known as Industry 4.0 is the holistic integration of information and communications technologies and forward-looking production and automation technology in factories.

Regardless of the question of whether this is a revolution or not rather an evolution through convergence of existing technologies from production and information technology – the potential is enormous. Processes are becoming more efficient, increasing data availability is creating new bases for decision-making, and intelligent products allow new kinds of insights into the life cycle. As a result, business models are also changing: holistic networking and digital interfaces for machines, for example, allow innovative business and payment models.

A look at the past of industrial upheavals shows: Each of the previous revolutions had far-reaching effects on almost all areas of society. Completely new technological and economic possibilities opened up, combined with opportunities for further innovations at a wide variety of levels. Thus, Industry 4.0 also comes with the tools for a multi-layered industrial – but also overall societal change. As with the other industrial revolutions, this change is not sudden, but steady and unstoppable.

As the world market leader, DMG MORI accompanies its customers holistically through this digital transformation along the entire value chain. The technology leader with a broad, diversified customer structure has a global presence. As a “Global One Company”, DMG MORI pursues the mission: “Empower our customers in manufacturing and digitization” with the aim of making its more than 100,000 customers from 54 industries in 86 countries sustainably successful. The latest machine tools, automation solutions and digital products pave the way for manufacturing that is also future-proof for further industrial revolutions.

Learn more about our joint path into the future here!