11/29/2021|General Article

The machine tool as the mother of all machines

With the transformation to industrial production in the 19th century, the history of the machine tool took off. The steam engine, as a key technology, enabled the mechanization of the drive of production machines. From then on, this motorization replaced human muscle power and unleashed enormous potential. To this day, the importance of machine tools for industrial production as a whole remains unbroken. Many of the products we use every day have only become possible through the use of tools and machine tools.

The role of machine tools

The world would not be what it is today without machine tools. Machine tools allow a workpiece to be machined using tools. This process is followed by a movement of the tool and the workpiece in relation to each other, dictated by the machine. Depending on the manufacturing process, a distinction is made between primary forming, forming and cutting machine tools. Especially the high accuracy and almost unlimited geometrical machining variety ensures the outstanding position of the cutting machine tools also for the future.

The development of the machine tool has changed the world and shaped the progress of mankind. Almost all industrial goods are produced through the use of machine tools. Without machine tools there would be no engines, no aircraft engines, and no electronics in noble aluminum housings – the list could be continued almost endlessly. Machine tools are industrial production. It is not without reason that one speaks of the “mother of all machines”.

In particular, innovation-driven economies such as Germany and Japan impressively demonstrate the importance of the machine tool industry. They set the pace in the industry at a very early stage and have developed ever more powerful and precise machine tools. This in turn has played a key role in shaping progress in other industrial sectors: Ever higher-quality implants in medical technology, ever more sophisticated lightweight materials in the aerospace sector, or ever more productive manufacturing systems in automotive engineering – machine tools have always set the stage for innovation.

Today, the DMG MORI portfolio ranges from the compact DMP 35 to the XXL machining center DMU 600 Gantry linear.

The machine tools of tomorrow

DMG MORI Digital Twin: The increasing convergence of mechanical engineering and information technology results, among other things, in the digital twin of a machine tool.

Despite all the technological progress, established manufacturing processes are not losing their importance. Further increasing demands on surface quality as well as ever higher dimensional, form and positional accuracies will continue to make metal-cutting machine tools an integral part of the global store floors in the future.

Even with a view to the possibilities of new processes such as additive manufacturing, a coexistence with unique advantages is already establishing itself through the clever combination of classic and – in this case – additive technologies. Designers have more freedom in the design of products as well as in the integration of functions.

In addition, precision, productivity and reliability, as well as an ever higher degree of automation and the need for increasingly flexible manufacturing solutions, determine the development of future machine tools. This development is influenced by new technologies and the increasing convergence of mechanical engineering and information technology.

Future from tradition

DMG MORI has been developing technological milestones since 1870, also at GILDEMEISTER in Bielefeld.

DMG MORI is a technology leader with tradition. The company has been developing technological milestones since 1870. Progress and the courage to explore new paths have been an integral part of its DNA for over 150 years. This has made DMG MORI one of the largest machine tool manufacturers in the world. On the foundation of this tradition and supported by the strategic pillars of automation, digitization and sustainability, DMG MORI is forging ahead with the convergence of mechanical engineering and digitization. To the same extent, the company is transforming itself from a pure machine tool manufacturer to a holistic value-added partner and pioneer for its customers.

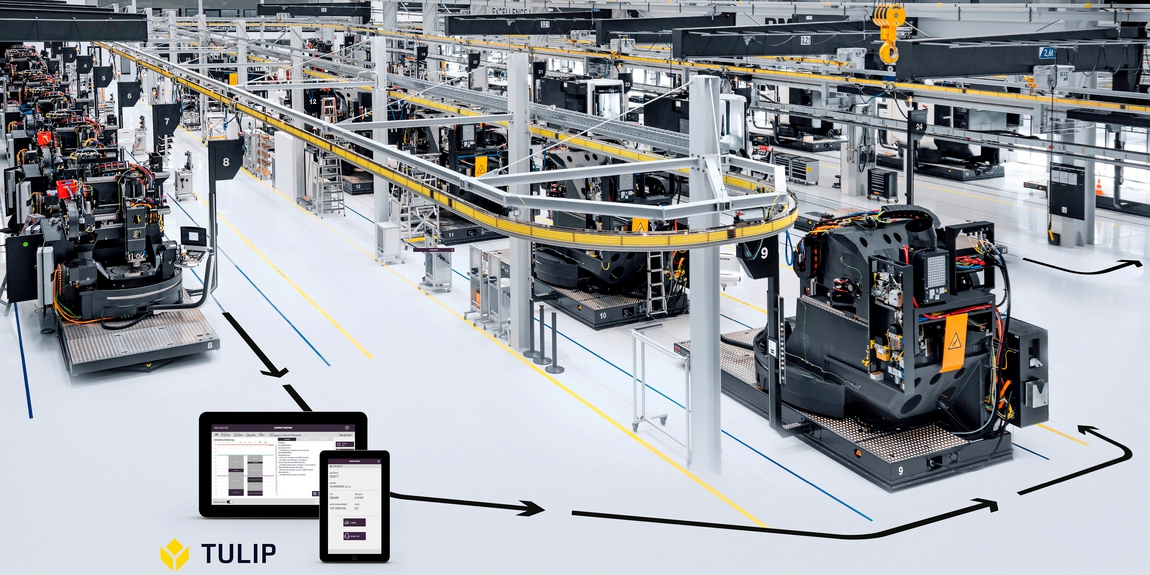

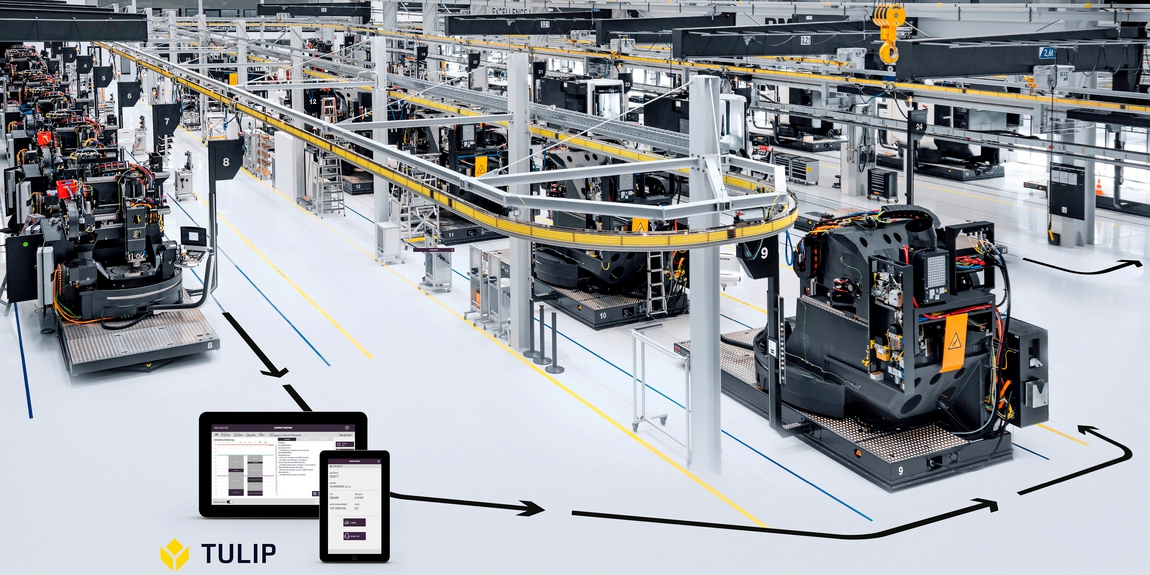

Excellence Factory monoBLOCK at DECKEL MAHO Pfronten: machine tool manufacturing is also becoming increasingly modern.

Read more now

Special technical articles, analyses and background information on topics that move our industry.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Discover exclusive content with your DMG MORI Account.

Activate technical data now

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Activate download now

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Register now and unlock exclusive content

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Login now to access your shared documents

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Activate history now

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Activate favourites now

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Activate favourites now

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.